Products & Services

Products & Services

Protocase manufactures fully finished custom electronic enclosures and associated parts from a wide variety of materials and components, in 2-3 days with no minimum order. Protocase also provides expert and affordable enclosure design services.

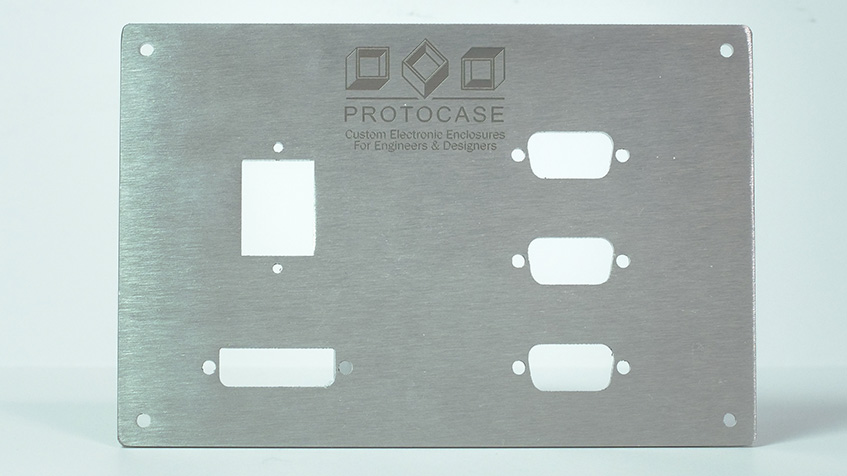

Laser Marking

Laser marking is an ultra-precise, efficient means of permanent marking that offers an enormous amount of versatility. Also known as etching or engraving, laser marking is the ideal way to permanently mark your enclosure or part for labeling, serialization, branding or schematics.

Laser Marking Types:

Laser marking offers several different kinds of marking, with each achieving a specific aesthetic and texture. Depending on your requirements, you may employ more than one type of laser marking within your custom enclosures, parts and panels.

Engrave:

This type of mark is created by removing material to create a mark that has depth, with the end result of an embossed look. The engraving depth can vary from minimal to extreme, depending on the time allowed for the marking process. If choosing engraving, please specify to your Protocase Account Manager the ideal level of depth for your engraving.

Burn:

This type of mark is created by aggressively burning the surface of the material. Depending on the substrate, the mark will vary in color from medium brown to black and black-grey. Post burn, the material’s surface will feel rough to the touch and feature areas of rise and fall.

Silver:

This type of mark is created by frosting the surface of the material at high speeds, which will result in a bright or white-colored marking. The end resulting mark may have a slight texture to the touch, but the surface or coating penetration is minimal, if at all.

Outline:

This type of mark is a simple line etch of the profile, with very little depth. To the touch, the outline mark will be very minimal.

Ablate:

This type of mark is created by removing the surface coated layer of a material, whether powdercoat or anodizing. This usually results in a bright or white-colored mark when contrasted with the coating. For this reason, ablate laser marking is aesthetically strongest when it is contrasted with a darker color (such as black, blue, red, etc). Once completed, the mark is relatively smooth with minimal surface penetration.

Anneal:

Available only on stainless steel, this type of mark is created by applying a large amount of heat to the stainless steel while minimizing the aggressiveness of the mark. The end result is a solid mark with a surface finish that is smooth.

Anneal is available in five different colors:

• Anneal (Default Option)

• Anneal Black

• Anneal Blue-Silver

• Anneal Sunset-Gold

• Anneal Green

Note: Colors may alter if there is a large amount of text or graphics being laser marked, as there will be additional heat. For example, laser marking in Anneal Green may turn slightly gold.

Materials

Laser marking in Engrave, Burn, Silver, Outline and Ablate is available on sheet metal and CNC machined aluminum panels, parts and enclosures, so long as the material thickness is 0.051” or greater.

Laser marking in the Anneal category is exclusively available for sheet metal and CNC machined stainless steel panels, parts and enclosures, so long as the material thickness is 0.051” or greater.

If you require laser marking on materials other than aluminum or stainless steel, contact us to discuss your needs.

Finishes

We offer laser marking on a variety of finishes:

- → Grained Finish

- → Powdercoat (Ablate only)

- → Anodizing

- → Chemical Film Conversion Coating

- → Media Blasting

- → Vibratory Finish

- → No Finish

Constraints

| Maximum Part Size | 28“ x 31” x 12.46“ (711.2mm x 787.4mm x 316.4mm) |

| Maximum Mark-able Footprint | 23.62” x 23.62“ (599.44mm x 599.44mm) |

| Maximum Height of Face Being Engraved | 12.46” (316.4mm) |

Font Capabilities

In order to achieve legible and clear laser marking, the minimum font size for all types of laser marking is 4pt font (0.056” | 1.42mm).

Please contact us for more information.

MIL-STD-130 (Table II)

Laser Marking is a permanent part marking method which is recommended for applications requiring MIL-STD-130 (Table II).

This standard provides criteria for the selection of the application process, as well as all other specific requirements that will be part of the deliverable item, such as marking protocol, content, font size, type, location, etc.

Simply stating in the product definition data that the marking be in accordance with MIL-STD-130 is not sufficient. The item identification marking requirements must be determined by the Design and/or Acquiring Activity in their contractual instruments, and tailored to meet the needs of their specific application.

Protocase is recognized solely and exclusively as the Manufacturer.

The customer is recognized as the Design Activity. They retain full design and quality assurance control, as well as full responsibility to the acquiring activity for the delivered product.

.jpg)

.jpg)

.jpg)